High speed disperser is a kind of equipment for mixing, dispersing and stirring various substances, which is widely used in chemical, food, medicine, material science and other fields. According to different classification standards, high-speed dispersers can be divided into many types. The following is an introduction to the main categories of high-speed dispersers:

First, classification by structural form

Bucket type high speed disperser

Features: The material is put into the bucket, and the material is quickly dispersed by rotating the dispersion sheet inside.

Application: Suitable for processing large quantities of materials, common in industrial production.

Desktop high speed disperser

Features: Compact structure, usually placed on the table, through the rotation of the spindle and dispersion sheet to mix and disperse materials.

Application: Suitable for use in laboratory or small-scale production.

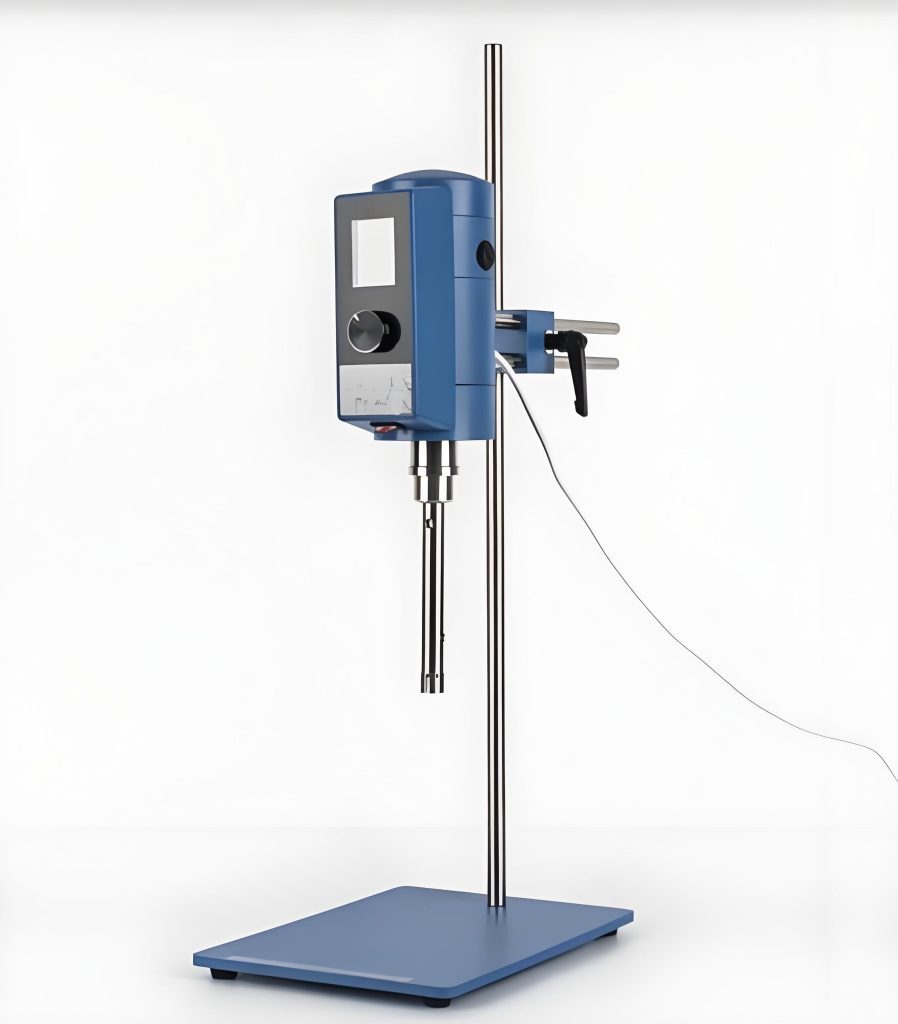

Elevating high speed disperser

Features: Equipped with lifting device, the height of the disperser can be adjusted according to needs, easy to operate and maintain.

Classification: It can be further divided into hydraulic lift disperser, electric lift disperser, pneumatic lift disperser, etc.

Application: Suitable for the treatment of various viscosity materials, widely used in chemical, paint, ink and other industries.

High-speed disperser for autoclave

Features: Specially designed to be installed in a reactor or container to mix and disperse materials by rotating dispersion plates.

Application: Suitable for mixing and dispersing materials in closed containers.

Second, according to the type of dispersion disk classification

Standard dispersion disk

Features: Traditional structure of the dispersion plate, suitable for various types of material dispersion.

Working principle: Rely on the shearing force generated by the teeth around the disk in the process of high-speed rotation to disperse the material.

Turbine dispersion disc

Features: Mainly suitable for dispersing materials with high viscosity and high solid content.

Working principle: The propeller-like part in the middle of the dispersion disc produces a downward force during high-speed rotation, which promotes the material to move downward from the hole in the middle of the dispersion disc to achieve efficient dispersion.

Plus dispersion tray

Features: Improved design based on standard dispersion disk.

Working principle: The material in the upper part of the dispersion plate is transferred downward through additional holes with guidance to achieve the purpose of effective dispersion.

ET dispersion disk

Features: An additional metal plate is erected on the disk surface to accelerate the mixing effect.

Note: Although the probability of collision between the filler and the metal sheet is increased, the presence of additional metal sheets may cause the follow-up phenomenon of the material during the high-speed dispersion process, affecting the dispersion effect.

Third, according to power source classification

Electric high speed disperser

Features: Use electricity as a power source.

Application: Suitable for mixing and dispersing all kinds of materials.

Pneumatic high speed disperser

Features: Use gas as a power source.

Application: Suitable for mixing and dispersing materials in special environment.

Hydraulic high speed disperser

Features: Use liquid as a power source.

Application: Suitable for mixing and dispersing materials in special environment.

Manual high speed disperser

Features: The use of manpower as a power source.

Application: Suitable for small-scale material mixing and dispersion.

Fourth, according to the application field classification

High speed disperser for chemical industry

Features: Designed for the characteristics of chemical materials.

Application: Widely used in pigment, dye, paint, ink and other fields.

High speed disperser for food industry

Features: In line with food hygiene standards.

Application: Used for mixing, mixing and homogenizing food raw materials, such as sauces, condiments, jams, chocolate, etc.

High speed dispersers for the pharmaceutical industry

Features: Meet the requirements of drug production.

Application: For drug mixing and dispersion, such as preparation of suspension, emulsion, capsule liquid filling, etc.

High speed disperser for medical device industry

Features: Suitable for the manufacturing process of medical devices.

Application: For the preparation of medical glue, medical paste and other products.

Fifth, other classification methods

Classification by scale: It can be divided into small high-speed dispersors (suitable for laboratory use) and large high-speed dispersors (suitable for industrial production).

Classification by function: It can be divided into ordinary high-speed dispersors (suitable for general material mixing and dispersing) and special functional high-speed dispersors (such as explosion-proof dispersors, high temperature high-speed dispersors, etc.).

In summary, there are a variety of classification methods for high-speed dispersors, and users can choose the right type according to actual needs and material characteristics.