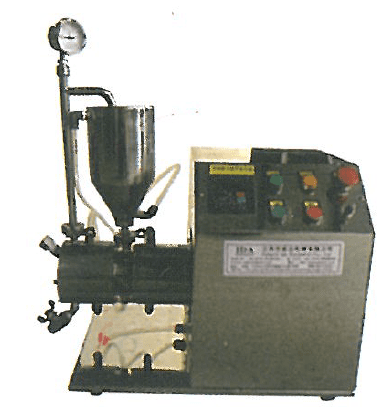

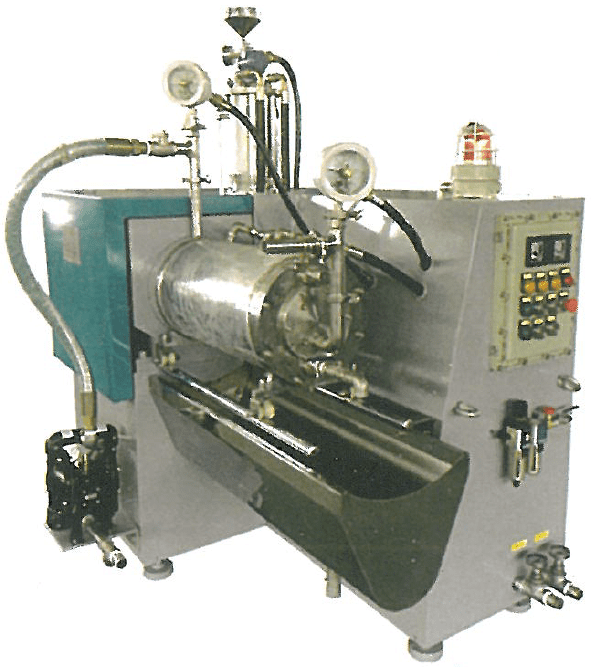

Application

automobile paint, ink, emulsion paint, black carbon, titan white power,industry coatings, pigment, colourant.

Basic technical parameter

| Ttype | IWS-0.5L | IWS-5 | IWS-20 | IWS-30 | IWS-50 | IWS-100 | IWS-250 | IWS-300 | IWS-500 | IWS-1000 |

| Motor power | 3-4KW | 5.5-7.5kw | 18.5-22kw | 22-30kw | 37-45kw | 55-75kw | 75-90kw | 90-132kw | 160-200kw | 315-355 kw |

| Effective grinding chamber volume | 0.5L | 0.5L | 20L | 30L | 50L | 100L | 250L | 300L | 500L | 1000L |

| Output | 5-60L/h | 10-100L/h | 50-250L/h | 100-500L/h | 200-1000L/h | 250-2500L/h | 250-2500L/h | >2000L/h | >3000L/h | >5000L/h |

| Finess (um) | 2-20 | 2-20 | 2-20 | 2-20 | 2-20 | 2-20 | 2-20 | 2-20 | 2-20 | 2-20 |

Feature

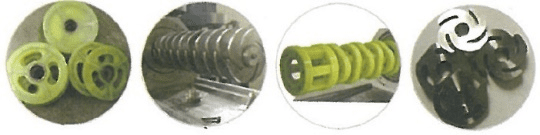

◆For the special requirements from the clients, much material can be chosen for the lWS horizontal bead mi’s grinding cylinder and dispersing disc, such as zirconium oxide, Teflon, compound material, etc. They have the features of solvent-proof, zero pollution and high wearing resistance.

◆Exchangeable, through-hardened front & end plates and hardened wear bushings at exposed locations.

◆Bead retention by centrifugal implement screen.