Application

car paint, special ink, carbon black paste for textile pigment, sub-micron grinding, electronic paste industry water based printing color paste.

Basic technical parameter

| Motor powe | ILM-10 | 22-30KW |

| ILM-20 | 45-55KW | |

| ILM-40 | 90-110KW | |

| ILM-80 | 250KW | |

| Effective grinding chamber volume | ILM-10 | 10L |

| ILM-20 | 20L | |

| ILM-40 | 40L | |

| ILM-80 | 80L | |

| Speed-modifying method for motor | ILM-10

ILM-20 ILM-40 ILM-80 |

Stepless Frequency inverter control |

| Main motor rotation speed | 0-1400rpm | |

| Suitable dimeter for grinding beads | 0.3-1.2mm | |

| Dispersing method | Centrifuga | |

| Sealing | double-end face | |

| Operating panel | Explosion button box/ Touch screen | |

| Equipment controlling | PLC control/ Conventional explosion-proof control circuit | |

| Specification | ILM-10 | 1286×750×1725mm |

| ILM-20 | 1450×900×2000mm | |

| ILM-40 | 1615×1050×2275mm | |

| ILM-80 | 1780×1300×2550mm |

Feature

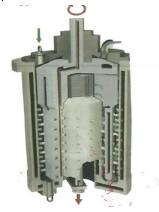

◆It is very easy to add grinding media from the filing hole above.

◆The centrifugal separator/the protective screen can be taken out from the closed mill easily.

◆Internal cooling device with large cooling area, can effectively takes away the heat to make sure the temperature of material in the safe scale.

◆It is very simple to make the grinding chamber decline by an integral lifting device.