The working principle of the high-speed disperser is mainly based on the generation of centrifugal force and shear force, and the material is rapidly dispersed and evenly mixed by a high-speed rotating agitator or agitator assembly. The following is a detailed introduction to the working principle of the high speed disperser:

First, overview of the working principle

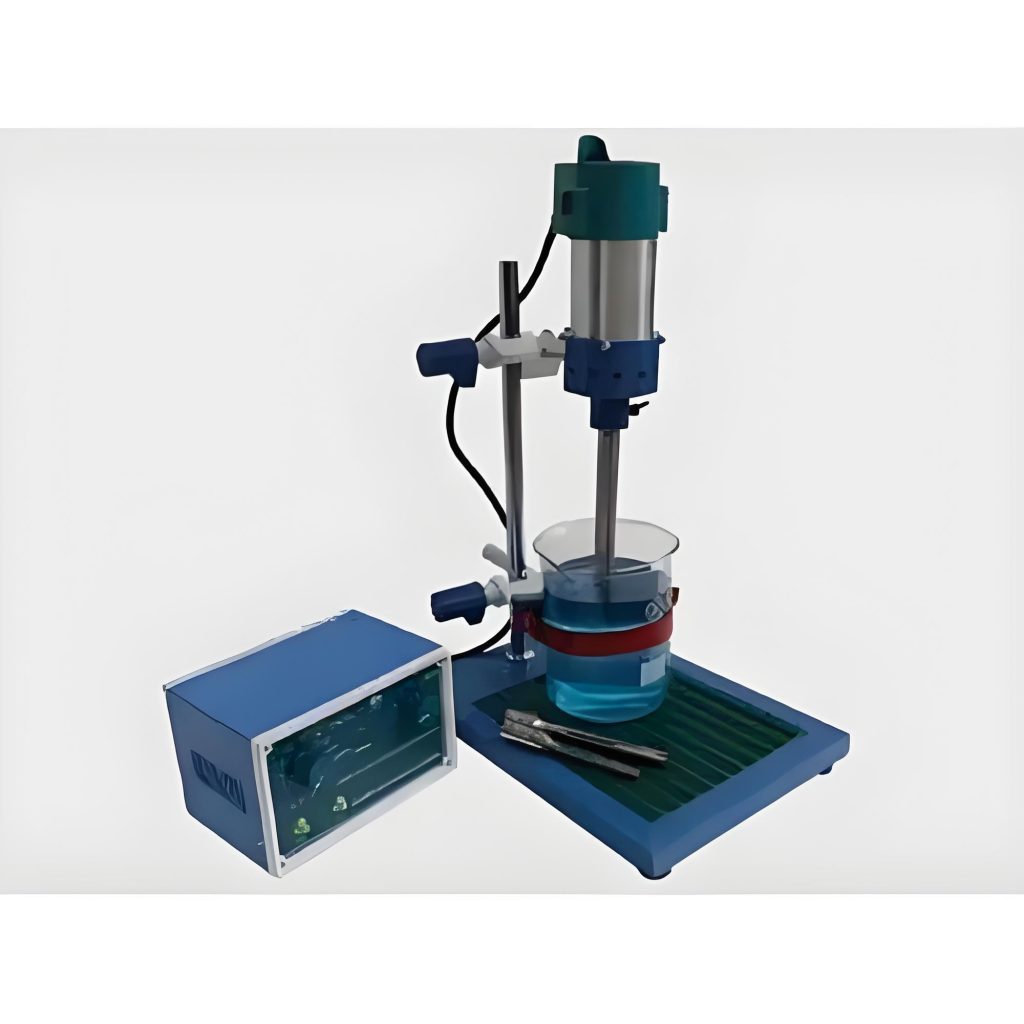

High speed disperser is a device that uses centrifugal force to mix liquid phase and solid phase in full contact. It produces powerful hydraulic shear and high-frequency mechanical effects in the container through a high-speed rotating agitator, so as to achieve rapid mixing, dispersion and homogenization.

Second, detailed explanation of the working principle

Material suction and initial mixing

When the high-speed disperser is started, its high-speed rotating agitator (such as a zigzag circular dispersion disc) begins to rotate at high speed under the drive of the motor.

The rotation of the agitator will create a strong centrifugal force in the container, throwing the material from the center of the container to the edge, forming a whirlpool like motion.

During this process, the material is initially sucked into the area near the mixer to prepare for the subsequent dispersion process. At the same time, the material under the action of centrifugal force will also start the initial mixing.

Strong shear and impact effects

High-speed rotating agitators (such as dispersion disks) produce extremely high linear speeds, usually more than 15 meters per second.

This high-speed rotation makes the material fully dispersed and broken under the action of strong hydraulic shear, liquid layer friction, tear collision and so on.

A turbulent zone will be formed near the edge of the agitator, and the material particles in this region will be subjected to strong shear and impact, so as to quickly disperse into the liquid phase.

Circulation and turning of materials

Due to the high-speed rotation of the agitator, the material is continuously emitted from the radial high-speed, and then changes its direction under the resistance of the material itself and the container wall.

In this process, the material will form two strong turbulent currents above and below, so as to achieve full circulation and turnover of the material.

This helps to ensure that materials at different locations in the container can be effectively dispersed and mixed to avoid uneven local mixing.

Further dispersion in laminar flow

Under the blender or in the bottom area of the container, the material may appear laminar flow.

In this state, the slurry layers with different flow rates will diffuse with each other, further promoting the dispersion of the material through the action of viscosity shear forces.

Intelligent control system

Modern high speed dispersors are usually equipped with intelligent control systems, through the control panel can precisely adjust the mixing speed, time and other parameters.

This precise control helps to optimize the dispersion process and improve the dispersion effect and efficiency.

Third, the application and effect of the working principle

The working principle of the high speed disperser enables it to be widely used in many industries such as chemical, paint, ink, food, and medicine. Through the centrifugal force and shear force generated by the high-speed rotating agitator, the material can be evenly mixed and dispersed in a short time, improving product quality and production efficiency.

For example, in the coating industry, high-speed dispersors can quickly disperse solid particles such as pigments and fillers into liquid media such as resins and solvents to form uniform and stable suspensions or solutions; In the food industry, high-speed dispersors can evenly mix various raw materials (such as sugar, salt, milk powder, etc.) together to prepare food products with delicate and stable quality for export.

In summary, the high-speed disperser realizes the rapid mixing, dispersion and homogenization of materials through the centrifugal force and shear force generated by the high-speed rotating agitator, which provides strong support for the development of multiple industries.